California-based textile and linen manufacturer and supplier collaborated with Fujitsu to develop a process to fully automate RFID tag insertion process

Venus Group is a global textiles manufacturer and distributor based in Foothill Ranch, CA. The company provides bed linens, towels, medical scrubs and more to industries such as hospitality, hotel, food and beverage, and healthcare worldwide. Manufacturing is Venus’ strength, but the company is always looking for ways to innovate and improve its processes to meet industry needs.

The Problem:

For businesses that rent or provide textiles and linens, managing and handling items is a major pain point. Sorting, counting, packing and separating clean and soiled linens uses manual labor and is prone to error. Additionally, there is no accurate way to account for loss. Solving these problems requires individual identification of each item. RFID resolves these issues, but installing an RFID tag on every individual item can be labor intensive and time consuming.

That is why Venus Group worked with Fujitsu to develop a solution that would save the company time, virtually eliminate physical handling of items, and help its customers streamline inventory management.

In order to stay on the cutting edge of manufacturing and linen tracking, Venus worked with Fujitsu to integrate RFID technology into its fully automated manufacturing process.

Manually sewing RFID tags into linens would slow down Venus’ state-of-the-art production system, which is one of the company’s unique advantages. So, Venus and Fujitsu collaborated on a solution that would automate the RFID tag insertion process.

The Solution:

Fujitsu Frontech North America is a leader in RFID technology. Fujitsu UHF RFID linen tags are designed to withstand industrial washing and dry cleaning, and are virtually undetectable when installed. With a small form factor allowing them to be sewn into seams, Fujitsu RFID linen tags are ideal for flat linens and garments.

With RFID tags installed, thousands of linens can be read in seconds without having to scan individual barcodes. This makes managing soiled and clean linens easy, and improves asset tracking to reduce loss.

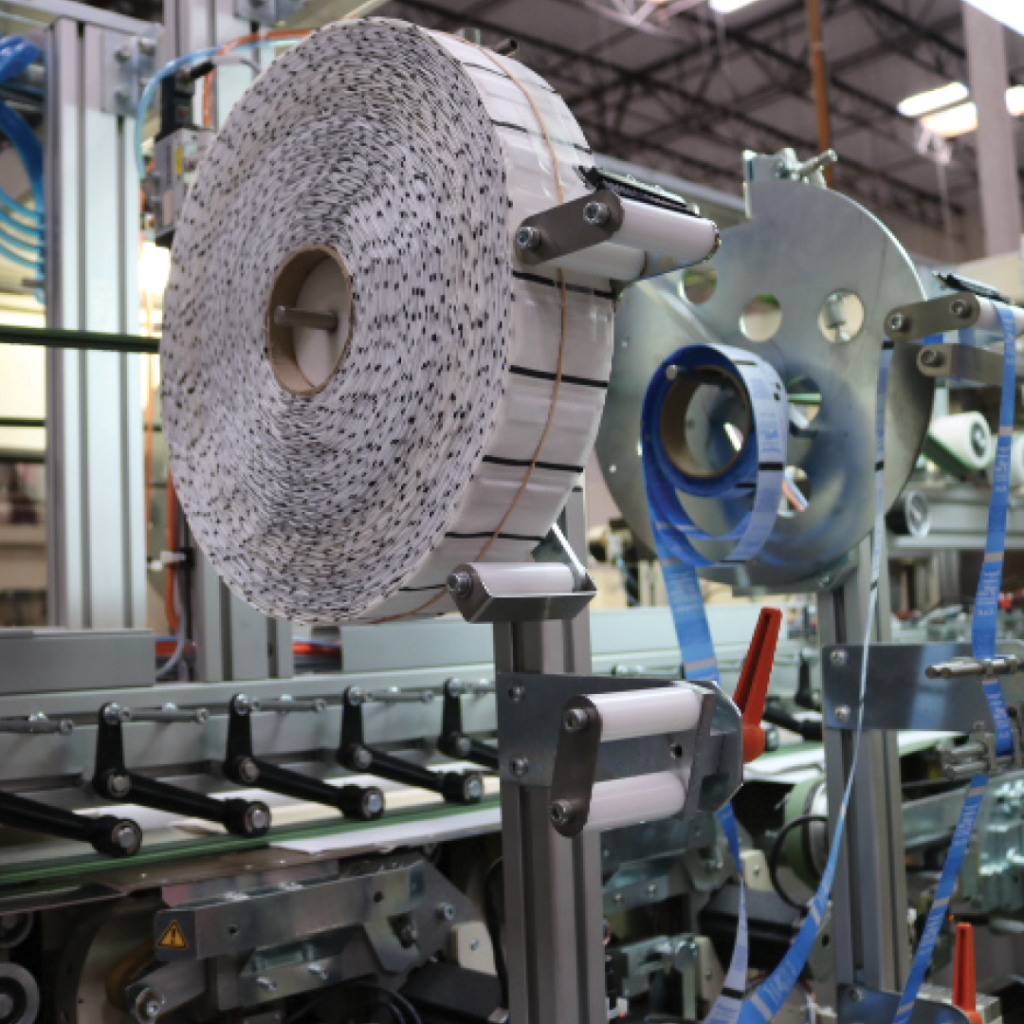

To fully automate the process of inserting the Fujitsu RFID tag into a Venus manufactured linen, the two companies created a continuous roll of custom-designed RFID tags in fabric pouches. Each pouch includes an embedded RFID linen tag and a cut line with a heat seal. During the automated manufacturing process at Venus, the RFID pouch is cut off the roll and inserted into the hem of each linen, then sewn into the item.

This process reduces the amount of manual labor needed to integrate RFID solutions and provides consistent quality for each linen. The heat seal prevents RFID tags from slipping out of linens, while the fabric material protects the tag from fraying and damage.

The Result:

After successful tests, Venus Group Table Linens embedded with Fujitsu RFID tags were successfully commercialized beginning in 2019.

With Venus’ manufacturing strength combined with Fujitsu’s washable RFID tags, the result is a superior quality linen with advanced functionality that is shipped to the customer quickly. The automation system manufactures linens expeditiously, while RFID technology allows the customer to be as efficient as possible when managing linen inventory.

Venus Group’s automated manufacturing process fully integrates RFID tags, providing customers in hospitality, food and beverage, and healthcare industries with a complete solution for textiles and linens.

About Venus

Venus Group, founded in 1972, is a privately held business headquartered in Foothill Ranch, CA. A business founded in textiles, Venus Group has evolved into a global company competing within numerous markets. The Group’s commitment to its customers has led it to explore various industries and develop smarter products through innovative technologies. For more information on Venus Group, Inc., please visit www.venusgroup.com